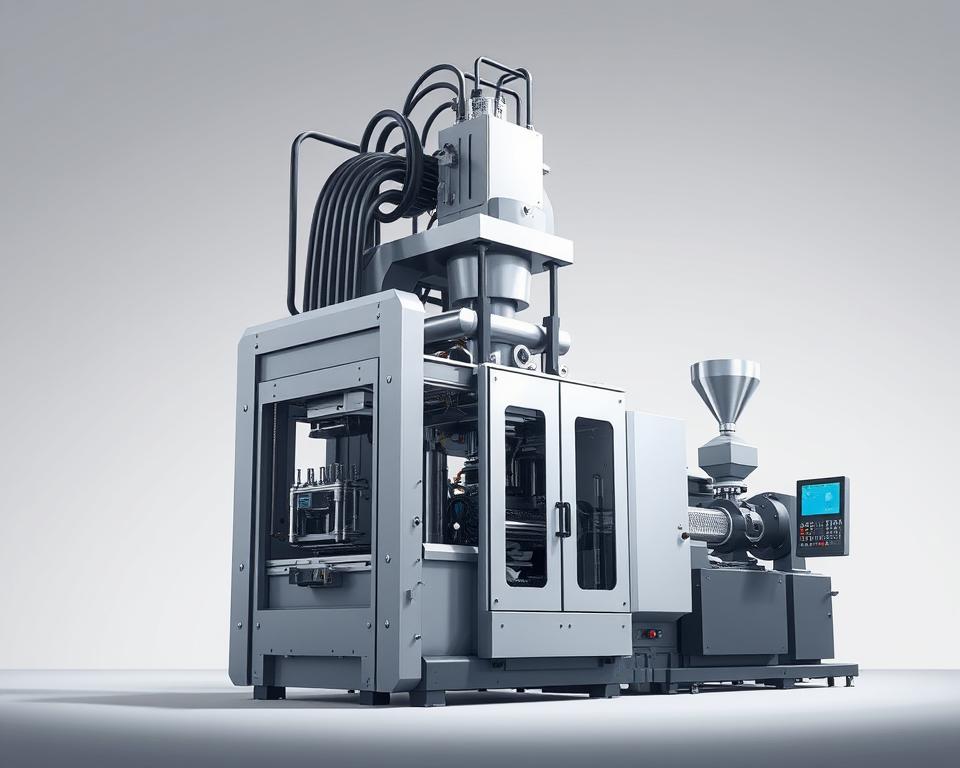

Guide to Engaging China Injection Molding Suppliers

Well, the major meeting has just concluded. your new product is a go, the schedule is tight, and the budget is, let’s say, constrained.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Of course, you acknowledge. It seems sensible at first glance. The cost savings can be huge. However, your brain is racing with concerns. You’ve heard the stories, haven’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

However, here’s the reality. Sourcing China injection molding doesn’t have to be a gamble. It’s no different from any structured project. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Ignore the nightmare anecdotes. Here’s a practical playbook to nail it.

First Things First: Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. Don’t assume a remote factory can guess your needs. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

What belongs in your RFQ?

Begin with 3D CAD models. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Add comprehensive 2D plans. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Avoid generic terms like “Plastic.” Even “ABS” alone is too vague. Be specific. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. What’s the reason? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Hunting for the Best Supplier

Okay, your RFQ package is a work of art. who gets your RFQ? The web is vast but overwhelming. Finding suppliers is simple; finding quality ones is tough.

Begin on popular marketplaces such as Alibaba or Made-in-China. They offer breadth but not depth. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Perhaps hire a local sourcing specialist. True, they charge a fee. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Another classic method? Trade shows. With budget permitting, Chinaplas or similar shows are invaluable. Meeting onsite is unbeatable. Inspect prototypes, interview engineers, and sense their capabilities. And don’t forget the oldest trick in the book: referrals. Consult trusted colleagues. A recommendation from a trusted peer is often worth its weight in gold.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, estimates roll in. You’ll see ridiculously low offers and steep quotes. Your job now is to vet these companies and narrow it down to two or three serious contenders.

What’s the method? It blends technical checks with intuition.

First, look at their communication. Are their replies prompt and clear? Do they communicate effectively in English? The true litmus: are they raising smart queries? The best firms will question and suggest. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Then confirm their machinery specs. Get their tooling inventory. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Then comes the audit. This is not optional. Just as you interview hires, audit suppliers. You can travel or outsource a local inspector. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Then comes the real action.

Initially, expect a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. It’s your first real test.

Expect T1s to need tweaks. This is normal! Look for small flaws, slight size errors, or surface marks. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold company samples. This process might take a couple of rounds. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Finally, a flawless part arrives. Dimensions, finish, and performance all check out. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Now comes full-scale production. How do you maintain consistency for part 10,000?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They’ll send you a detailed report with photos and measurements. Once you sign off, you greenlight shipping and the last payment. This audit shields you from mass defects.

Don’t forget shipping details. Understand the shipping terms, or Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re ready.